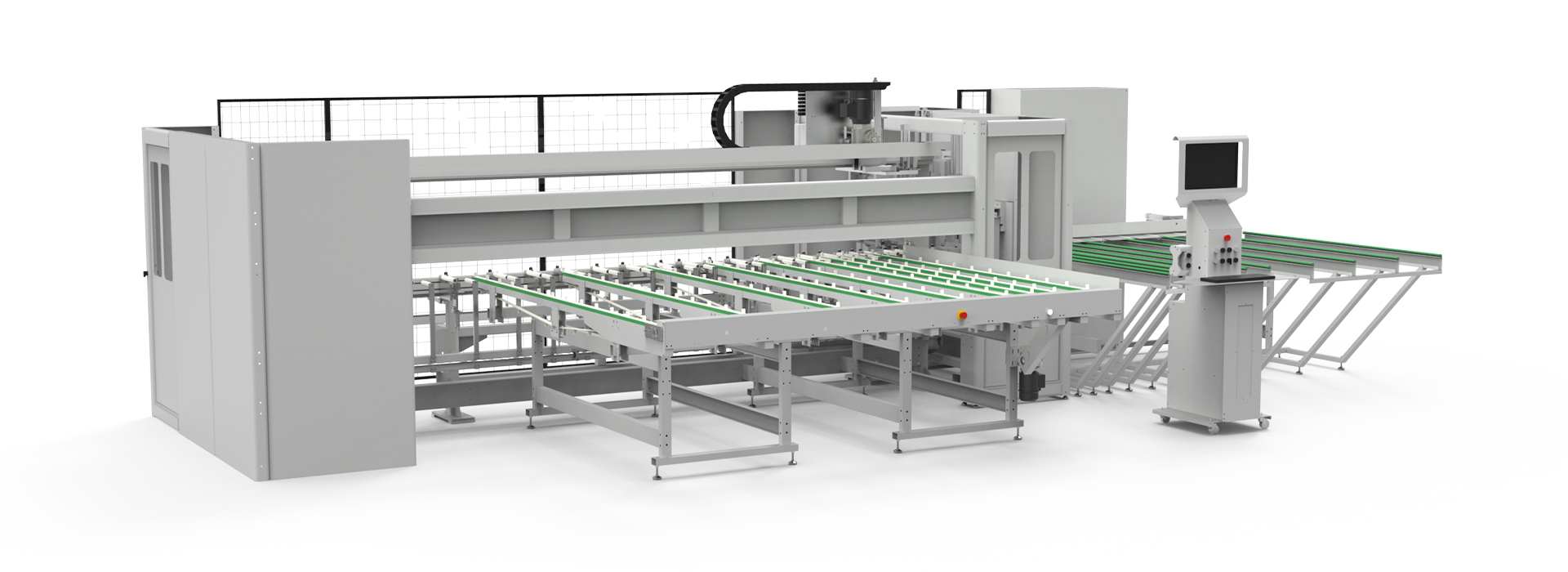

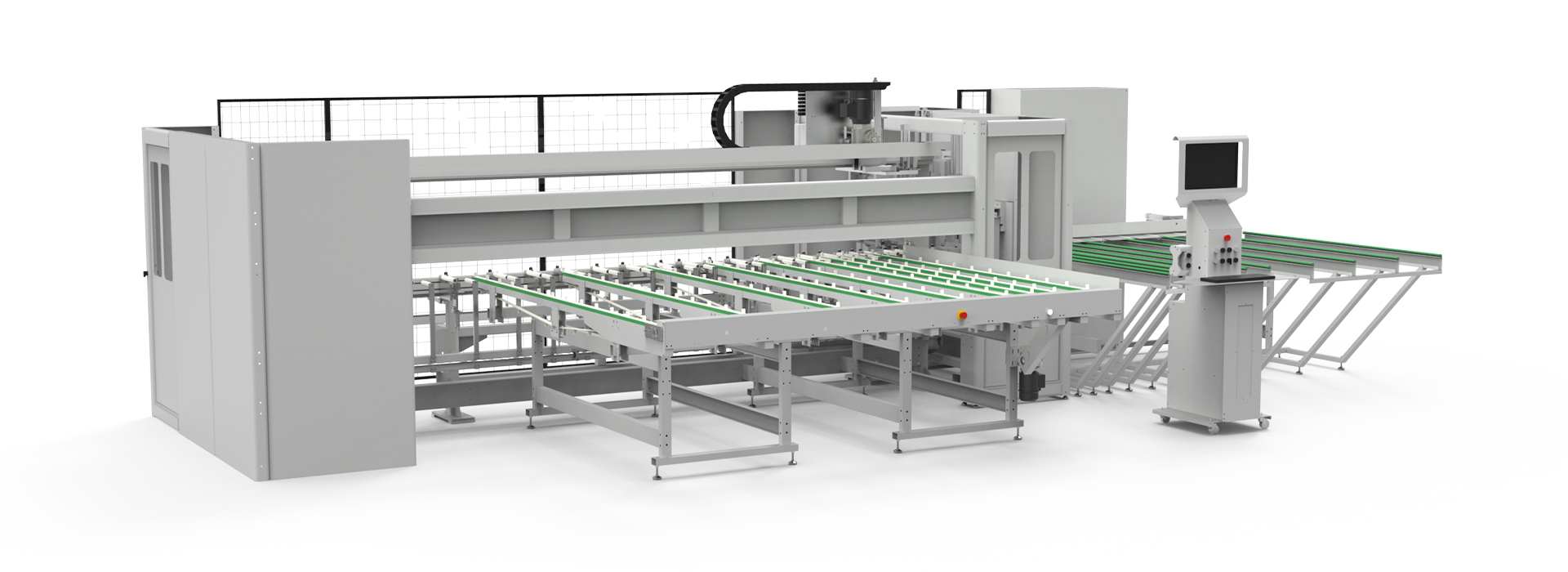

LMR12

Multi-spindle screwing and machining line

LMR 12 is a system which is fully commanded by a numerical control and produces the stiles and rails of door and window frames starting from cut profiles, machined entirely using an external screwing station and a multi-spindle unit.

The operator has to insert the metal reinforcement inside the profiles before arranging them on the loading unit feeding the screwing station, then moving on to the gripper unit which introduces the piece for the machining operations. The machining unit is equipped to carry out boring, screwing or milling on PVC profiles and relevant reinforcements.

The profiles are also marked to allow subsequent fitting of the hardware components.

- No. controlled axes 5

- Push loading feeder with 3 controlled axis gripper and pick-up on the inside of the profile and programmable pick-up position.

- Continuous, non-stop profile loading cycle of the profiles being machined.

- Piece length dimension check.

- Screwing in masked time of the reinforcement on external unit independent of the tool body

- PQCAM user interface software for simple, intuitive programming of machining operations on Windows platform

- Barcode reader

- Industry 4.0 ready

- Minimum transportable profile length: 400 mm

- Maximum transportable profile length: 3400 mm

- Useful loading capacity: 12 pieces

- Maximum permitted weight: 200 Kg

- Boring for wall mounting holes on frame. PVC and iron boring.

- Boring-milling of inclined condensation drain with 3 different programmable inclinations.

- Multiple boring system to machine the 3 handle bores simultaneously. PVC and iron boring.

- Boring-milling of top and rear condensation drains. PVC machining.

- Boring-milling of cremone bolt insertions. PVC machining.

- Marking of catches. PVC boring

- Through milling for lock insertion. PVC machining

- Screwing of steel reinforcement with 2 opposite screwing devices for door and frame

- Lower boring-milling. PVC machining

- 6-bit multi-chuck pre-boring for hinges on frame. PVC boring.

- Upper boring-milling. PVC machining

- Programmable 1-bit pre-boring for hinges on frame. PVC boring.

- STEP IN loading table

- Multispindle machining unit

- Mobile control console

- PQCAM user interface software for simple, intuitive programming of machining operations on Windows platform

- No. 4 0.4 kW electrospindles, 18,000 rpm

- No. 2 Asynchronous motors for machining of PVC and iron

- No. 1 pneumatic motor for marking of PVC.

- STEP OUT unloading table

- Sheet metal cab with safety entrance for maintenance and perimeter mesh guard

- Screwing of steel reinforcement with 2 opposite screwing devices for door and frame

- Lower boring-milling. Electrospindle 18000 rpm for PVC machining

- 6-bit multi-chuck pre-boring for hinges on frame. Asynchronous motor 2800 rpm. PVC boring.

- Upper boring-milling. Electrospindle 18000 rpm for PVC machining.

- Programmable 1-bit pre-boring for hinges on frame. Asynchronous motor 2800 rpm. PVC boring.

- Training courses for use of CAD/CAM software

- Remote assistance.